Now there are more and more types and styles of tiles. The style that customers want to present, tiles can do it for you. No matter it is noble and elegant or retro exquisite, different types of styles, tiles can present perfectly. But in the face of many brands, many tile terminology, are you confused and don't know how to choose the right tile for you? Today, sorted out some commonly used tile glossary of tilling and technical terms for you, hoping to help you.

Glossary of Tile Terms - Ceramic, Porcelain, Stone, Mosaic & More Tile Terms

Browsing through the below tilling glossary of terms on your hunt for a stylish new set of tiles, you might come across the odd phrase or term that you've never heard of before, the presented tile glossary will explain all.

Tile Terms: Types Of Tiles

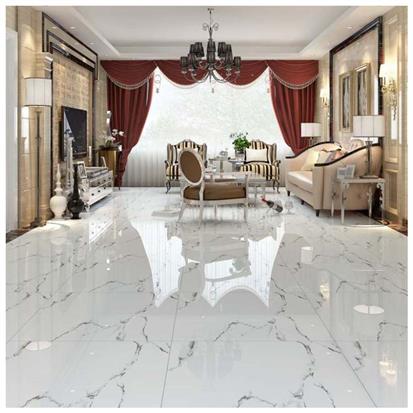

Porcelain tiles

Porcelain tiles are made of the dust - pressed method, it’s is similar to how ceramic tiles are made. But the Clay used in porcelain is much denser than the clay used in a ceramic. Porcelain tile has the texture of natural stone, but also has the advantages of high brightness, high hardness, high wear resistance, high anti-pollution, diversified specifications and rich colors. It is a common wall and floor material.

Terracotta Tiles

Fired using tunnel kiln with high temperature, the red and brown clays material are shaped into the desired tile design and form the extrusion bricks. The hardness, durability, and rustic look makes terracotta tiles to be a great flooring choice for rustic or natural settings, log cabin, indoor and outdoor areas, it's also ideal for building walls and roofs.

Mosaic Tile

Ceramic, porcelain, glass, metal or stone tile less than six square inches. May come in squares, octagons, hexagons or random shapes mounted for ease of installation.

Polished Tile

A polished tile is most commonly a porcelain or natural stone, that is mechanically polished with a fine abrasive diamond wheel to give it an extremely high shine. Not to be confused with a high glazed tile that has the glaze coating layered over the surface.

Lappato

A tile finish also known as "Semi-Polished". It will go through a similar process to a fully polished tile.

Glazed Tile

A tile that has an impervious facial finish composed of gaseous ceramic materials fused to the surface of the tile.

Tile Terms: Properties, Characteristics of Tiles

Water absorption

Under certain conditions, the ratio of water absorption and weight of tiles is water absorption. Water absorption is the most important index to measure the performance of tile. It reflects the degree of vitrification inside the tile. The lower the water absorption, the better the degree of vitrification, the less easy the product is to absorb dirt, and the more durable it is.

In general, the percentage of water absorption by pores in ceramic products is called water absorption. Specific calculation: water absorption = (m after water absorption - M before water absorption) / m before water absorption × 100%

Frost Resistance

Also known as the resistance to rapid cooling and heating, it is a sign to measure whether the tile can be used normally in the climate with great temperature change. This indicator deserves special attention in the climate with large temperature difference between day and night in the north.

Wear Resistance

Wear resistance is described by the volume of ceramic brick powder grinded under certain force, certain abrasive and certain revolution. The more ceramic brick powder grinded, the worse wear resistance. The tile with good wear resistance is resistant to heavy pressure, not easy to wear and tear. It is durable and new, especially suitable for use in public places.

Strength

The tile with good strength has strong crack resistance. The minimum compressive strength of national standard ceramic tile is 27mpa. The higher the strength of tile, the better the resistance to heavy pressure.

Radioactivity

Some special elements in the process of electron transition proton splitting, will produce some harmful radiation to human body, we put these elements of radioactive elements. Rustic tile basically does not have the radiation problem that is harmful to human body, so there is no need for 3C certification (3C certification is for polished tile).

Antifouling

If the tile surface is stained with dirt, the easier to wash it off, the better the antifouling performance. The determination of antifouling performance is to apply the standard pollutant easy to produce trace on the surface of the tile, after a certain time, use different kinds of cleaning agent to clean. Such as bleaching powder, washing powder, acetone, hydrochloric acid solution, potassium hydroxide solution and other commonly used cleaning agents.

Chemical Resistance

Refers to the resistance of tiles to the erosion of chemicals (such as acid, alkali, salt). Good chemical resistance, even in the long-term acid or alkaline environment, tiles will not change. Improving the chemical corrosion resistance can prolong the service life of tile in natural state. The stronger the anti pollution and anti-corrosion ability of tile, the more convenient the daily cleaning.

Glossiness

It refers to the strength of the reflective ability of the ceramic tile or polished tile surface. The higher the glossiness is, the stronger the reflective ability is. Then the surface looks like a mirror, and the light can be seen.

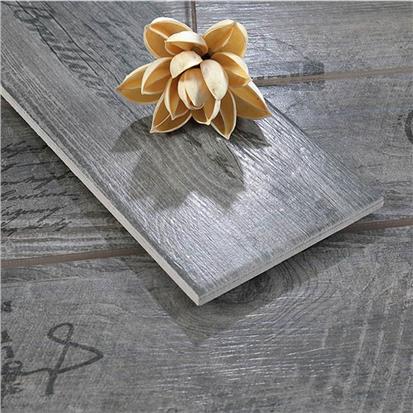

Glazed Finish

It adopts roller and illusory color technology to create three-dimensional glaze effect of metal, rock and sandstone. It has natural, modern and classical styles.

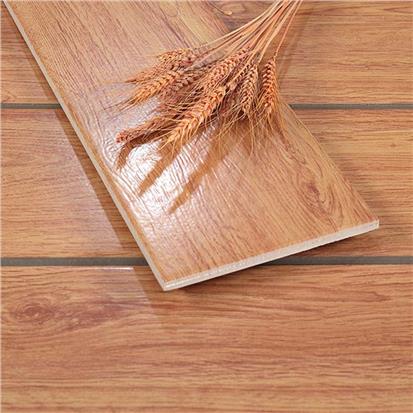

Pattern

Taking rustic tile as an example, the higher the nonrepeatability of pattern, the better the change, and the more realistic its naturalness; the smaller the color difference and the inconsistent texture, it is more suitable for large-area paving.

Tile Terms: Tile Defects Nomenclature

- Crack on body - The cracks appearing on the blank body shall not be found on the qualified tiles.

- Crazing - Micro cracks on glaze.

- Crawling - There is no glaze in the part of the body due to the aggregation and shrinkage of the glaze layer.

- Glaze bubble - Open or closed bubbles on glaze.

- Waviness ripple - The glaze is wavy.

- Scratches - There are traces of abrasives scratched on the polished surface of the product.

- Angle deviation - The angle of the product does not meet the requirements of the design regulations.

- Wedging - The length of the parallel sides on the front of the product is inconsistent.

- Polished trace - There are traces of abrasives scratched on the polished surface of the product.

- Omission from polishing - There is no light in the part to be polished.

- Blistering of bod - Open or closed blisters protruding from the surface of body.

- Smoked glaze - Due to the influence of smoke, the front of the product is gray or brown, or the glaze is partially or completely Matt.

- Speck - A block of mottling on the front of the product.

- Lamination - Lamellar cracks or separation in the body.

- Pinholes - Pinhole on glaze.

- Pinprick - Pinpricked holes in glaze.

Tile Terms: Materials Used For Tile Installation

- Adhesive - An adhesive or glue is a material, usually in a liquid or semi-liquid state, that adheres or bonds items together. Adhesives come from either natural or synthetic sources.

- Backing - Material used as a base over which a tile is installed.

- Caulk - Waterproof filler used to seal joints and make tile joints watertight.

- A substance that is applied to a suitable substrate to create a bond between it and a succeeding layer.

- Cement Board - A panel normally ¼" or ½" thick made of cement, reinforced with fiberglass used as a substrate for tile installation.

- Epoxy Adhesive - A two part adhesive system consisting of epoxy resin and epoxy hardener. Used for bonding ceramic tile or stone to backing material.

- Grout - A mortar used to fill the joints between tiles.

- Sealer - An elastic adhesive compound used to seal stone veneer and joints. It adheres to tile grout and joints; it protects against staining. If a stone is not sealed properly water will seep into the back.

- Sealing - Sealing makes a veneer watertight with an elastic adhesive compound. It is an application of a treatment to prevent staining.

- Back Buttering – The spreading of a bond coat on the back of a porcelain or ceramic tile immediately before the tile is installed.

EN

EN FR

FR PT

PT AR

AR