Tiles are a popular choice for flooring, countertops, and backsplashes in homes and commercial spaces. They come in many different shapes, sizes, colors, and textures which makes them highly customizable and versatile. But have you ever wondered how these tiles are made? In this blog post, we will take a look at the process of tile manufacturing from start to finish.

Raw Materials

Tile production starts with sourcing the necessary raw materials such as clay, sand, and other additives depending on what type of tile is being made. Clay is usually sourced from local areas where it can be mined or harvested from river beds or hillsides. The clay is then processed into a fine powder that can be used for making tiles by sorting out rocks, debris, and other impurities before mixing it with water to form a slurry paste. Sand is also added to the mix to give the finished product its strength after firing in kilns during production. Other additives like colorants may also be included for certain types of tiles if desired.

Preparation of the Clay

Once all of the raw materials have been gathered together they must then be prepared for use in tile production by filtering out any remaining impurities before aging them separately according to their particular requirements so they reach optimal consistency when mixed together later on down the line during production. Depending on what kind of end product is desired there are various methods used such as tempering (adding moisture) or drying (removing moisture). Once all preparations have been completed it’s time to move on to forming tiles!

Shaping the Tiles

The most common methods used to shape tiles out of clay include extrusion (passing them through an extruder), pressing (using molds or dies), or hand-forming (pinching pieces by hand). All these processes require specialized equipment such as presses and rollers so that uniform shapes can be achieved with minimal manual effort. Additionally, some factories may utilize 3D printing technology which allows them to create customized designs quickly and accurately without having to invest heavily in additional machinery or tooling costs.

Drying and Firing

After shaping each tile must then undergo two further steps before it's fully prepared for installation - drying and firing in a kiln at high temperatures until hard-baked. The exact temperature settings depend upon what type of material is being fired but generally range between 800°C–1200°C depending on factors like size/shape/thickness etc., while gas firing tends to produce faster results than electric ones due to its lower energy consumption rates overall. During this process, tiles are stacked up carefully inside specially designed containers called saggers which help evenly distribute heat throughout all parts ensuring consistent results every time!

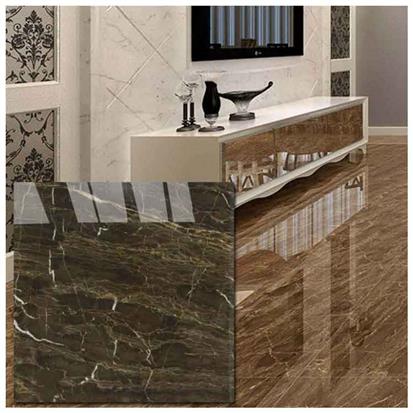

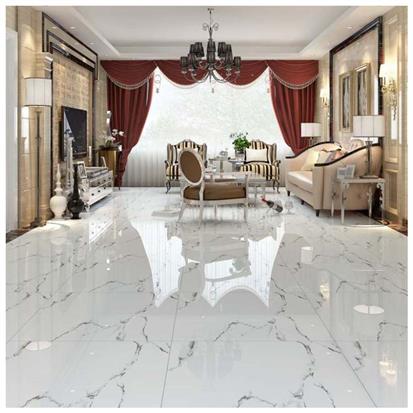

Glazing and Decoration

The first step in making tiles is adding glazes or other decorative elements to them. Glazing involves applying a thin layer of glass-like material over the tile surface which gives it color, texture, water resistance as well as protection against everyday wear and tear. Different types of ceramic glazes exist depending on what kind of aesthetic you’re going for; matte finishes create an elegant subdued look while glossy ones add more shine to your design project. As well as traditional methods like dipping or spraying the solution onto each piece, some manufacturers also use digital printing techniques for intricate designs such as mosaics or photo prints on large surfaces like flooring tiles – allowing endless possibilities when it comes to creating custom pieces tailored towards your tastes!

Quality Control

Quality control is an important part of ensuring high-quality end products when producing tiles - with size measurements being taken before they go out into stores so customers know they're getting consistent sizes across all batches produced by specific manufacturers. Other tests include strength testing where samples undergo cycles simulating years' worth of usage over time; this helps determine durability levels based on expected foot traffic etc., so you know what kind works best for different areas around your home (e.g heavier duty options may be better suited for busy hallways). Last but not least come visual inspection processes too: spot checks looking at factors like uniformity between colors/ textures within one batch, any defects present & whether there's been proper adherence during firing times (allowing even heat distribution throughout)

So that wraps up our overview on how modern-day wall & floor tiling solutions are manufactured today - from initial steps involving careful selection & blending of raw ingredients together followed by automated cutting + shaping then coating with decorative layers enhanced via digital printing technology; right through till final stages concerned with rigorous quality control procedures helping ensure satisfactory results every single time! No matter if it's interior décor projects seeking simple accents here n' there or complete transformations requiring larger scale changes, knowing basics about manufacture will help set expectations correctly while giving appreciation due to craftsmanship involved along the way.

EN

EN FR

FR PT

PT AR

AR