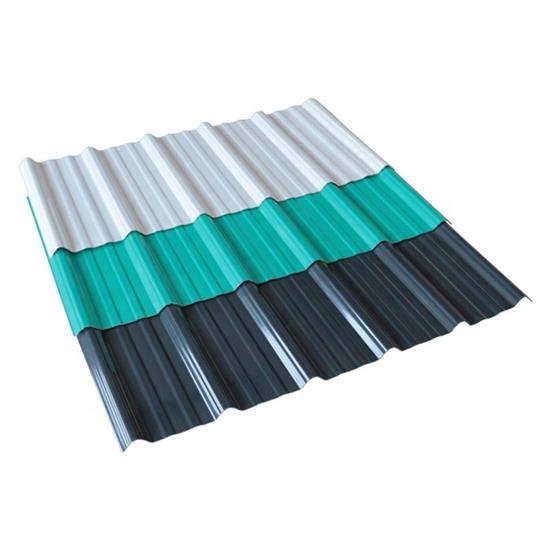

Blue 1 Ton Moq Light Weight Thermoacoustic Fibreglass Resin Synthetic Roof Panels Plastic Roofing Sheets Corrugated

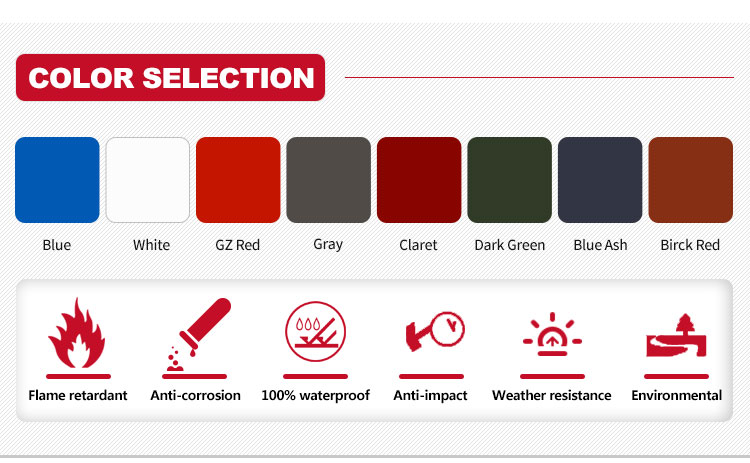

Product Feature :

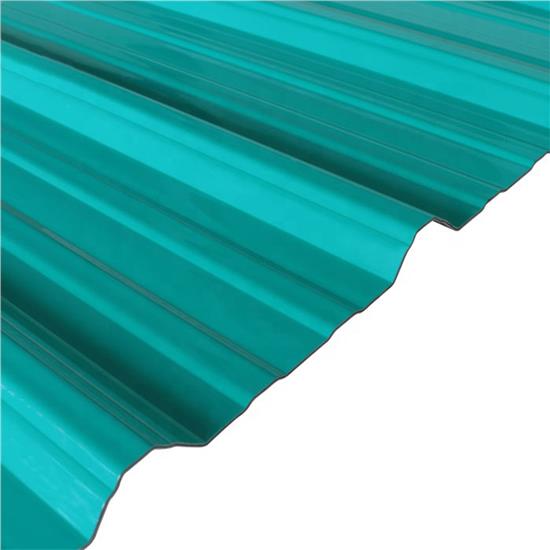

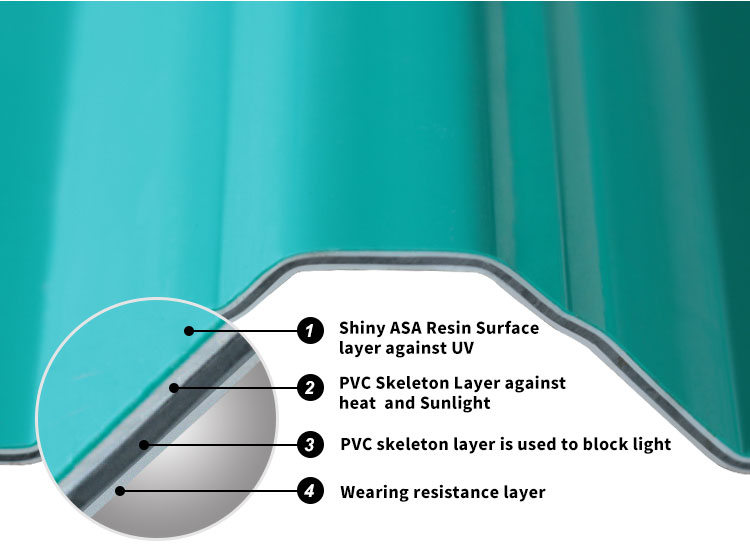

ASA composite roof sheet the surface material is extruded by super resistant resin surface layer,

and the surface resistance layer thickness ≥0.2mm, thus ensuring the durability and corrosion resistance of the product.

strong impact resistant, .30 years guarantee.

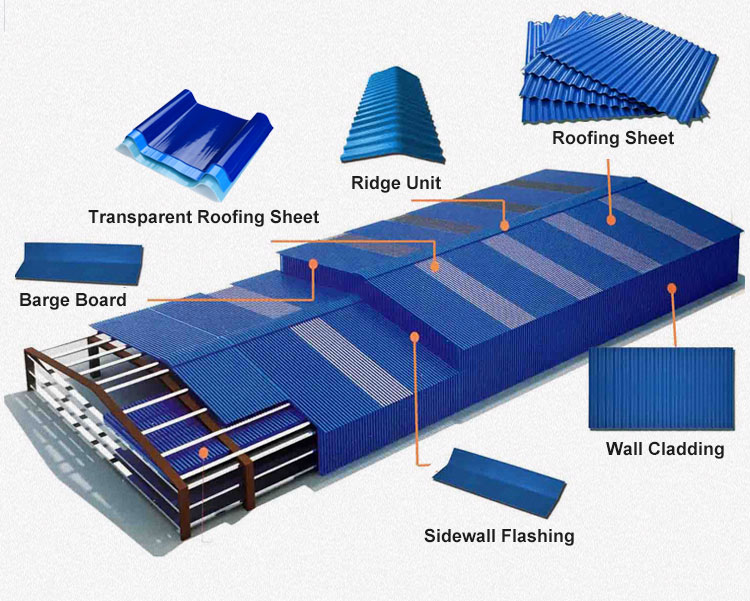

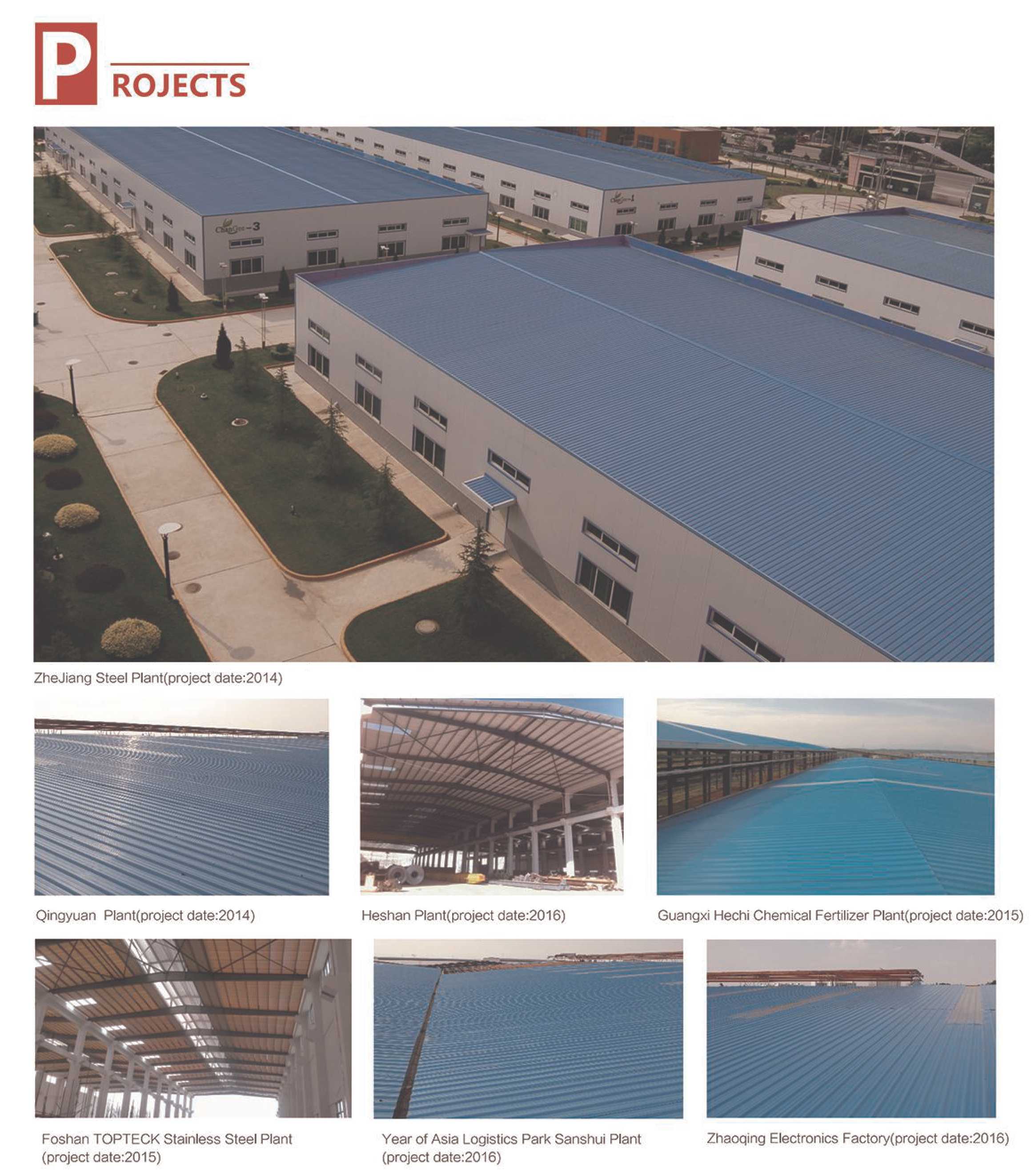

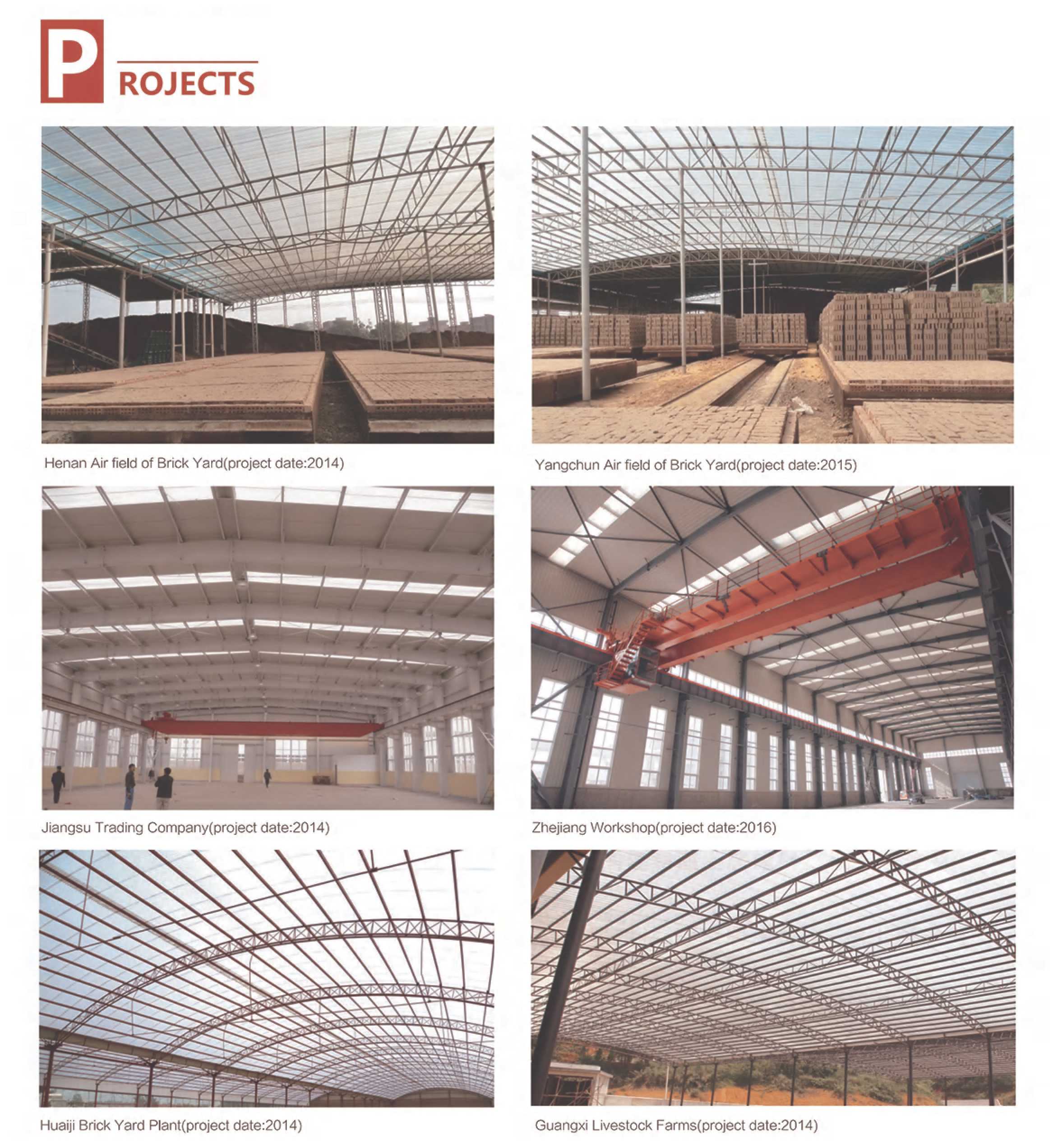

Application:

High-grade plants, steel factories, warehouses, farm market, sheds ,acid, and corrosive factory

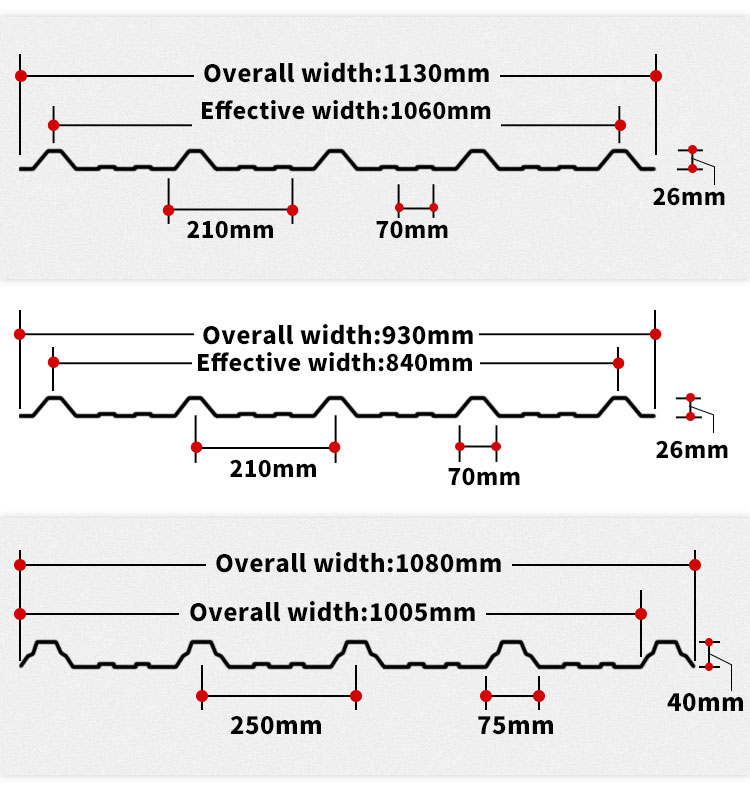

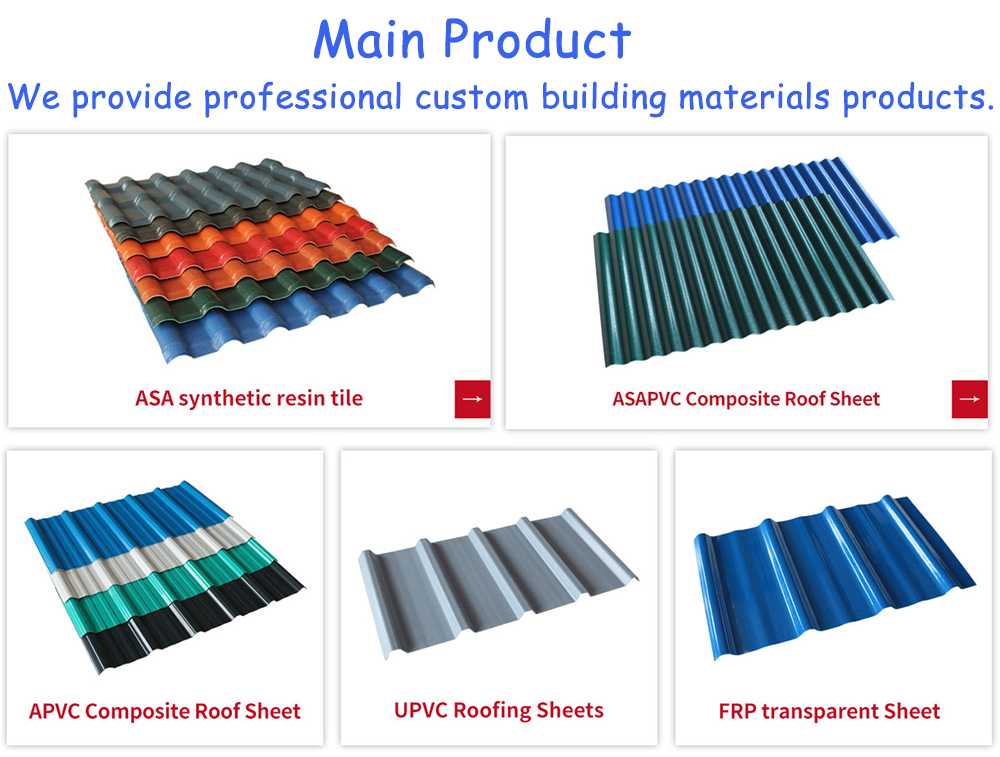

| Type | resin roof tile |

| Material | ASA synthetic resin/strong synthetic resin/ASA composite/A+PVC/PVC/FRP lighting board/PPC |

| Length | can be coustomized |

| Color lasting | 10 years no fading |

| Feature | noise/ heat insulation/ anti- Seismic/ easy to assembly/ disassembly |

Product performance:

1.Color Fastness:lasting color for 10 years

The surface material is made of super weather resistant ASA engineer-ing resin.It has

extraordinary durability in the natural environment.Color stability can be mainted even

under harsh conditions of ultraviolet light,moisture,heat and cold.

2.Excellent corrosion resistance

Synthetic resin tile can resist the corrosion of acid,salt and other chemical substances

for a long time.And phenomena of rust,spots etc.will not appear under various adverse urban

enviromental conditons like acid rain etc.

3.Strong impact resistance

According to the test,1kg steel ball falling freely from 3 meters high will not crack

synthetic resin tile,which has s strong bearing capacity of external impact.

4.Good load resistance

In low temperature climate,even if the roof under perennial snow,synthetic resin tile will

be not damaged or torn.The test also shows that the resin tile will not deform and fall

under the purlin distance of 880mm,and extra 60kg loated.

5.Good sound insulation

Resin tile has good sound insulation and silencing effectg.When exposed to external noised

such as raintorm and gale,it can be both sound insulated and noise absorpted.The test

results show that the average sound insulation volume is over 30dB.

6.Fire resitance

Resin tile materials belongs to the refractorty materials,and te fire rating meets

international CB 8624-2012 B1 level.

7.Convenient installation

Synthetic resin tile is easy to install,and tile installation is more efficient and cost-

effective.

8.Self cleaning

The surface of the resin tile is smooth and compact,which does not absorb wate4r,dust and

will be more clean and bright after rain wash.

Correct Installation methods and attention:

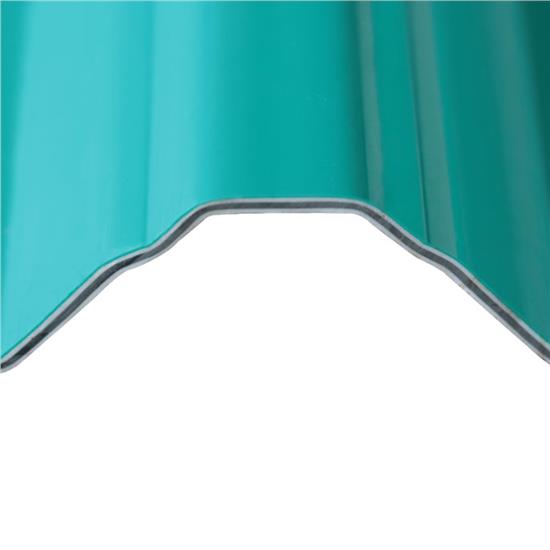

1.Correct placement of tile

a,overlapping (for roof length≤15m)

b,Interleaving (for roof length≥15m)

2.Correct use of special nail

a,The special nail must be nailed in the middle of the tile bone to be waterproof.

b,Fixation interval of special nails is 50cm~100cm,4pcs/m2 is better.

c,Special nails must be made from the lower end of the tile to the roof top to be more

beautiful,airtight and neat.

3.Install the seal ridge tile to seal off eaves cover

a,Separate the sealing strip in half, and cover the ridge tile according to tile shape on

the roof and fix with special nail.

b,Seal the joint of the lateral tile with cement,cover the ridge tile directly and end

bottom of ridge by smalls tiles.

c,To install and nail verge cover directly on the lower end of tile or roof eaves.

d,Ridge tile joints should be clipped with scissors to fit the interface,overlapped and

sealed with glass glue.

4.Waterproof treatment for protruding part

First,make a v-type material as water connecting,which can be different materials and

specifcations accordingly,fix it at the bottom and install color steel tile on it.

5.The connection and installation of the inclined plane

It refers to the construction of water connection at the bottom of two roofing tiles after

cutting off by angle and length.First,water connection materials(i.e.,gutter)are installed

under the tiles,and then finish with waterproof adhesive or cement.

Safety Precautions:

1.Wear necessary safety equipments,such as gloves,hard hats,safety belts,etc.

2.Installation workers must be certified professionals.

3.The skeleton must be firmly installed.

4.Walk on the tile,try to step on the middle part of the tile not the edge when

installation.

5.installation should be cautious in bad weather.

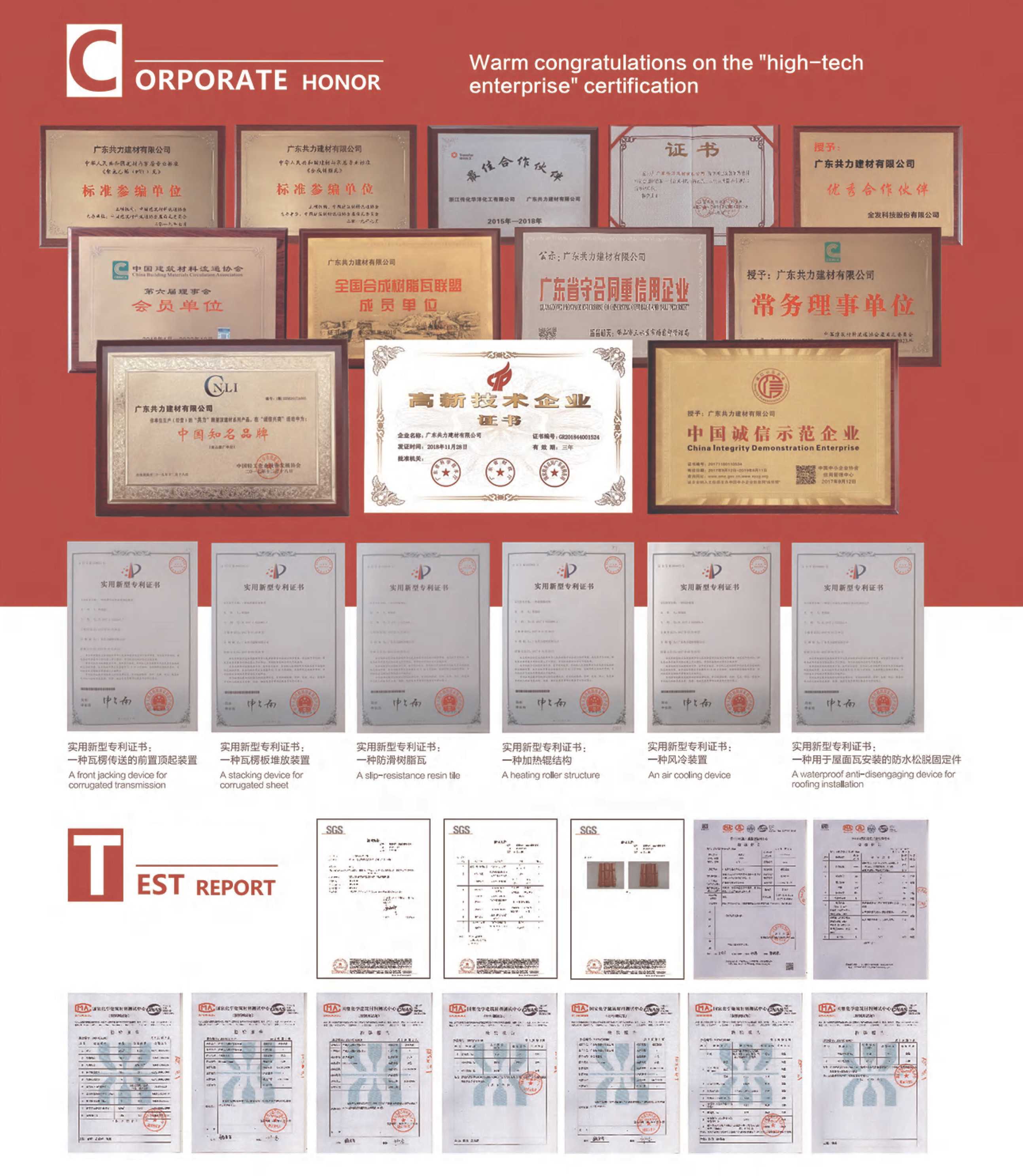

Corporate Culture:

FAQ:

1. How do I know your quality?

High solution detailed photos and free sample will be able to verify our quality.

2. Are you a trading company or factory?

We're factory. We manufacture products ourselves.

3. I'm a home owner and I need small quantity, what can I do?

Please check with our sales team if it's in stock or if we have distributor locally.

4. Can I get a door to door service? or can I get the tiles delivered to my door?

Yes, we offer delivery to your door service, which makes your work easy.

5. Can I get a sample first? And how does it charge?

Yes, free sample is available with freight collect or prepaid.

6. What if the tiles are broken during transition?

All our products are insurance, our after sales will sort our the reasons and will sure you'll be properly compensated.

7.Can you make products from our designs?

Yes, we do OEM and OBM.

8. How do I make payment?

We received PayPal western union and directly bank transfer to our company account. If above are all unavailable, we will issue you a PayPal invoice and you simply pay by credit card

If you have more query, please feel free to contact with us,thank you

-

P04

P04

P04Dark Grey Matte Floor Tile

300 x 300mm

-

HB024293

HB024293

HB024293Blue Glazed Porcelain Tile

900 x 1800mm

-

ASA-6

ASA-6

ASA-6Blue Material Termoacustic Composite Shingle Roofing For Sale For House Corrugated Roof Sheets Green

Customized Size

-

4966

4966

4966White Glazed Ceramic Tile

Customized Size

-

751504X

751504X

751504XBlue Glossy Ceramic Tile

75 x 150mm

-

HM3843LA

HM3843LA

HM3843LAWhite Glazed Ceramic Tile

Customized Size

EN

EN FR

FR PT

PT AR

AR