The commercial kitchen is a place with heavy lampblack, high humidity and high temperature. When it comes to tiling commercial kitchens, the installation is facing a harsh environment - the fats and acids in food and dishwasher spillage, the substrate, mortar, cleaning products, grout and tile are under constant attack by varying temperatures, boiling grease, bacteria, acidic cleaning techniques and the abundant use of water. So the decoration of the commercial kitchen has always been a matter of great concern to the operators. In order to help you fix all these issues, we present you 5 tips for installing tile in commercial kitchens contains some materials you will need, helping you significantly increase the value of your commercial kitchen installation.

5 Tips For Commercial Kitchen Tile Installation

You need consider some essential factors, preparations and materials options when installing kitchen tile or restaurant tile. Following these 5 tips you can significantly increase the lifespan and the value of your next commercial kitchen installation.

1. Choose the right preparation and setting materials

Choosing materials that can stand up to these tough conditions is critical. The demands on a kitchen floor begin as soon as the doors open, so you'll need to know exactly how quickly the installation will be used with new construction, you may have enough time to use a standard curing material but more commonly, the kitchen will require return to service in just a few hours. If the kitchen will be used right away, select rapid setting installation products, these products cure in a matter of hours to allow light traffic and you can get the facility back to work the same day. Every commercial kitchen floor will get wet frequently and the floors are usually pitched to a drain, prepare the substrate with a fast drying waterproofing and crack isolation membrane such as red guard for setting, heavy pavers and quarry tiles on these pitched floors. Your best option is to use a medium bed non-sag rapid setting mortar. An epoxy-based mortar is the most durable choice and should be specified for industrial use and resistance to chemical exposure.

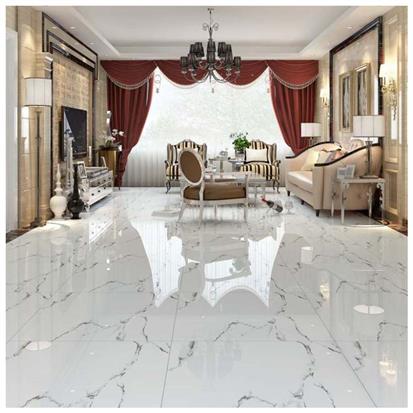

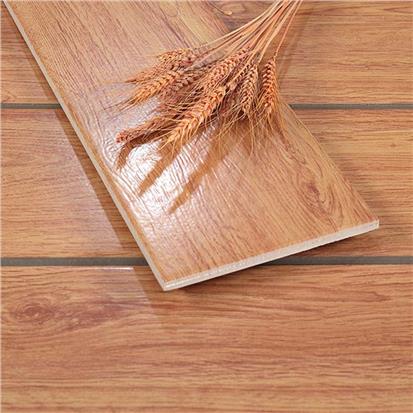

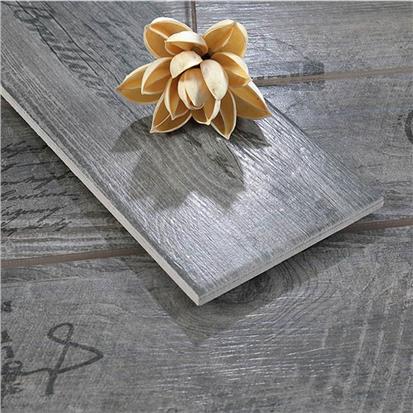

2. Select tiles that are appropriate for these very harsh conditions

The tiles you choose have to be durable and have high friction coefficient, and the slate floor tile and porcelain wall tile must be the best options. When a tile is broken, repairs should be made immediately, so the damage will not spread. The last thing you want is for dishwasher water to get under your tile system. Restaurants usually experience very heavy traffic with loaded carts hand trucks and other metal objects. Tile edge corners at walls, movement joints and doorway transitions are among the first to be damaged. You want to use a stainless steel or high-strength aluminum profile and transition wherever you can to prevent damage to the installation.

3. Waterproof kitchen tile floor & wall

Because of the excessive amount of moisture common in the commercial kitchen, there are some considerations such as waterproofing, wall protection and slip resistance of the tile. A wise consideration is to waterproof both the floor and walls. With excessive water, often the result of kitchens being hosed down in the cleaning process and the dishwashing area, a quality wall construction with a water-resistant substrate like concrete, a mortar bed or backer board is essential and waterproofing should be part of the design.

4. Use an industrial grade epoxy grout

Commercial kitchens are frequently cleaned and scrubbed, often with aggressive chemicals and high temperature water. Many of these chemical cleaners along with pressure washing, can severely damage both tile and grout. Protecting the integrity of the grout is a vital component of a successful kitchen. Commercial kitchens require the highest performance industrial grade epoxy grout available, so choose a grout that is highly chemical stain and heat resistant, which should also have excellent resistance to fatty acids that will be encountered throughout the lifetime of the installation.

5. Install a complete system with a warranty

A manufacturer system warranty should cover installation materials, tile and labor for at least ten years, and this protects the architect, the contractor, and the property owner a complete system is installed from the ground up using the right preparation materials, the right mortar, and the right grout to protect the tile.

EN

EN FR

FR PT

PT AR

AR